Enhance Your BIW Assembly Planning

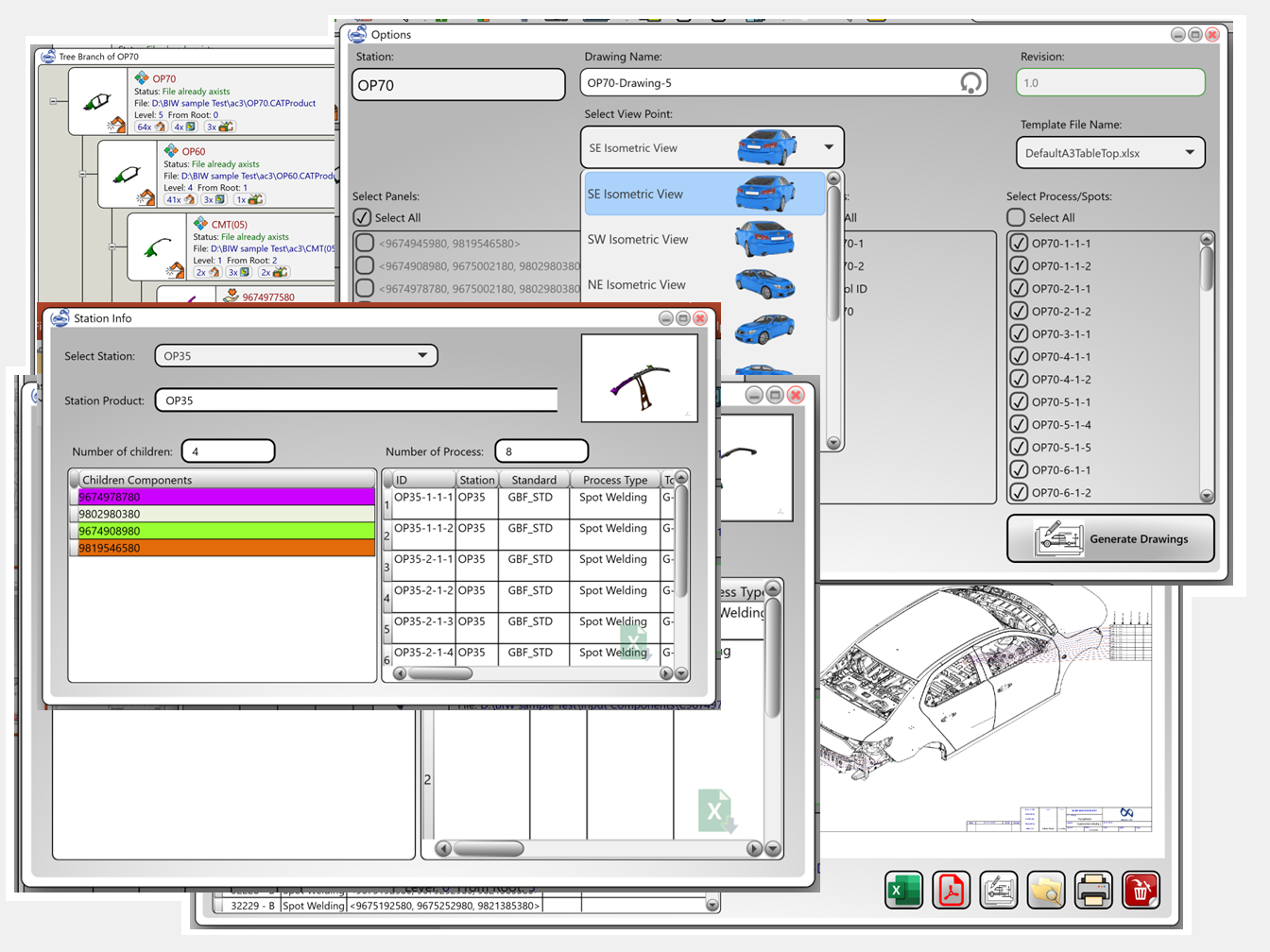

BiW Assembly Planner automates creation of CAD files, documents and drawings of your BIW (Body-in-White) project.

What is BiW Assembly Planner?

BIW-AP is a software designed to assist in planning the assembly process in BiW production lines. It:

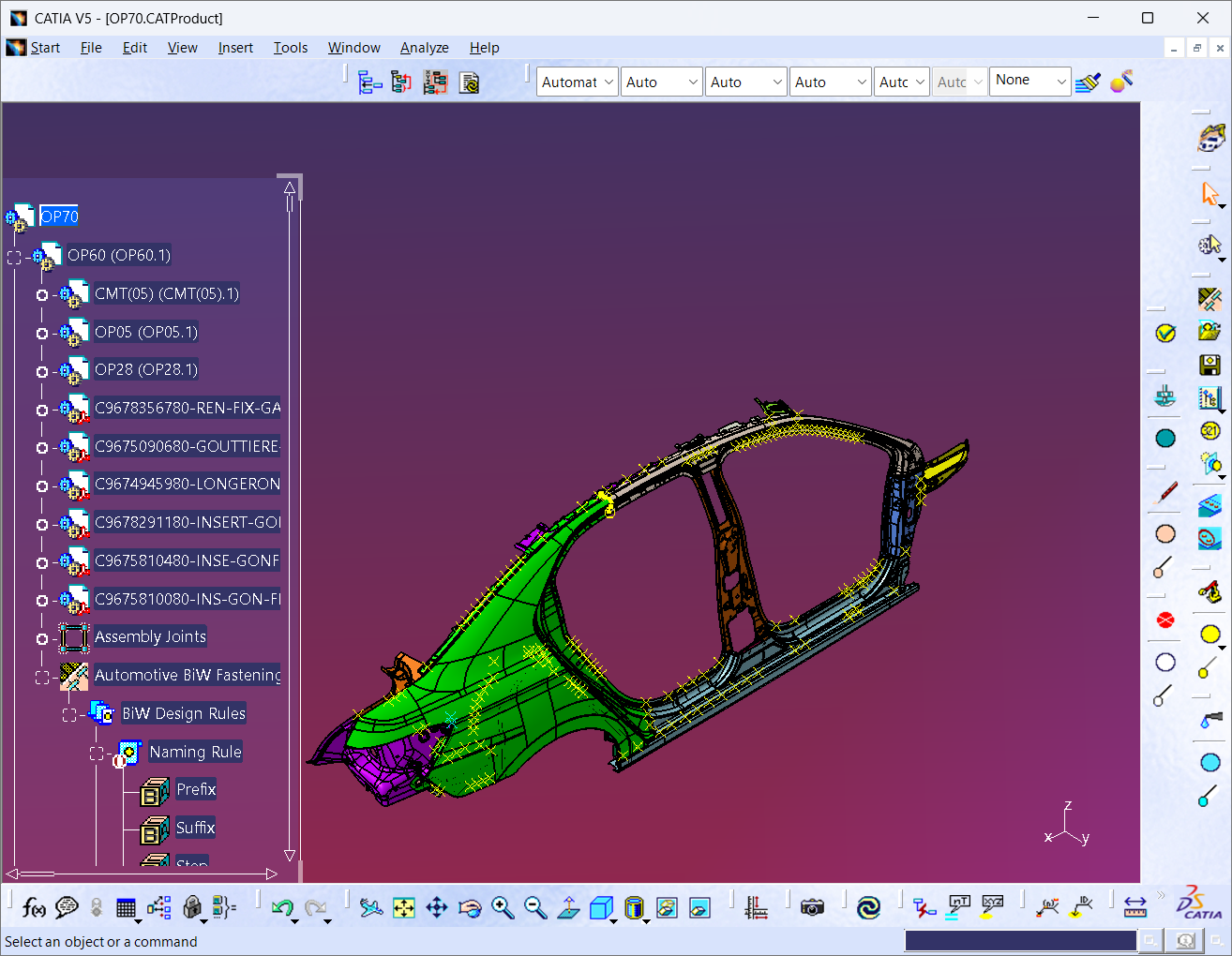

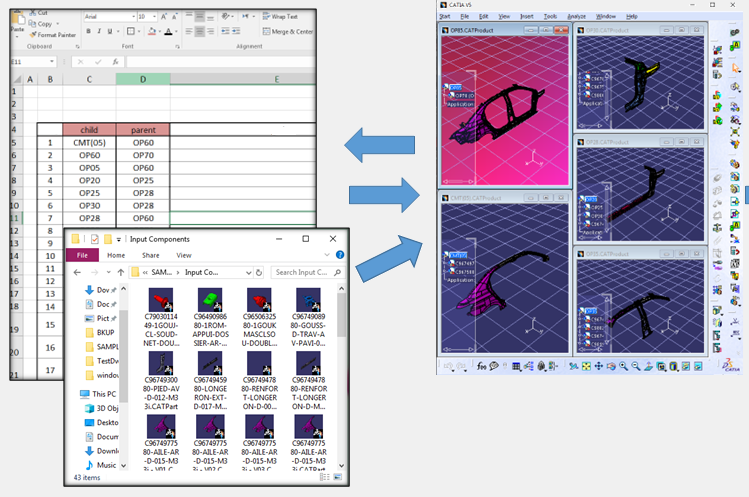

- Reads Plant BOM from Catia® CAD files or BOM tables,

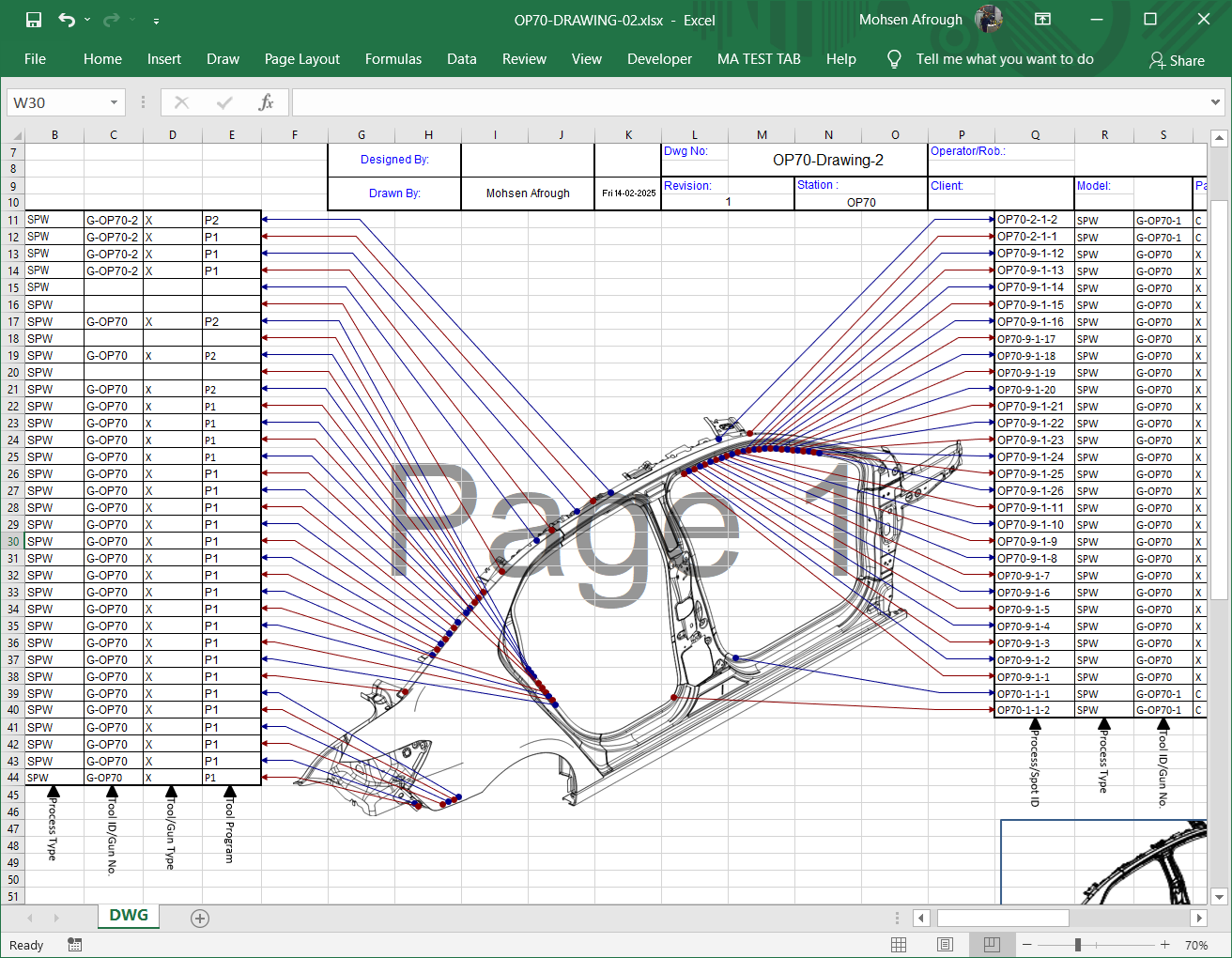

- Automatically creates process sheet drawings,

- Handles Spot weldings, Rivets or Mechanical Joinings, MIG/TIG/Laser Weldings, Glueing, Sealing etc. or your customized process definitions,

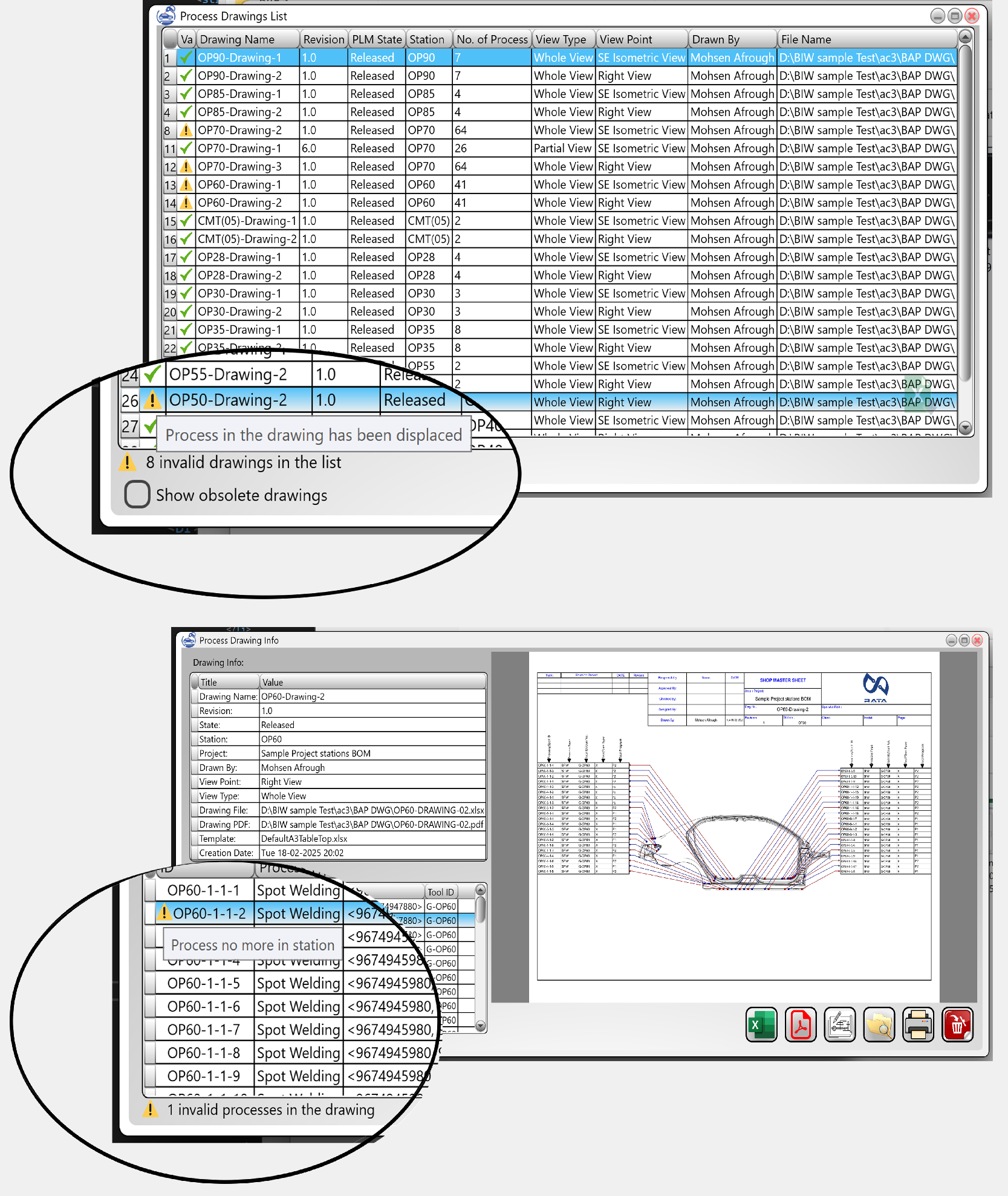

- Checks the validity of drawings concerning changes in the sequence of assembly/process plan,

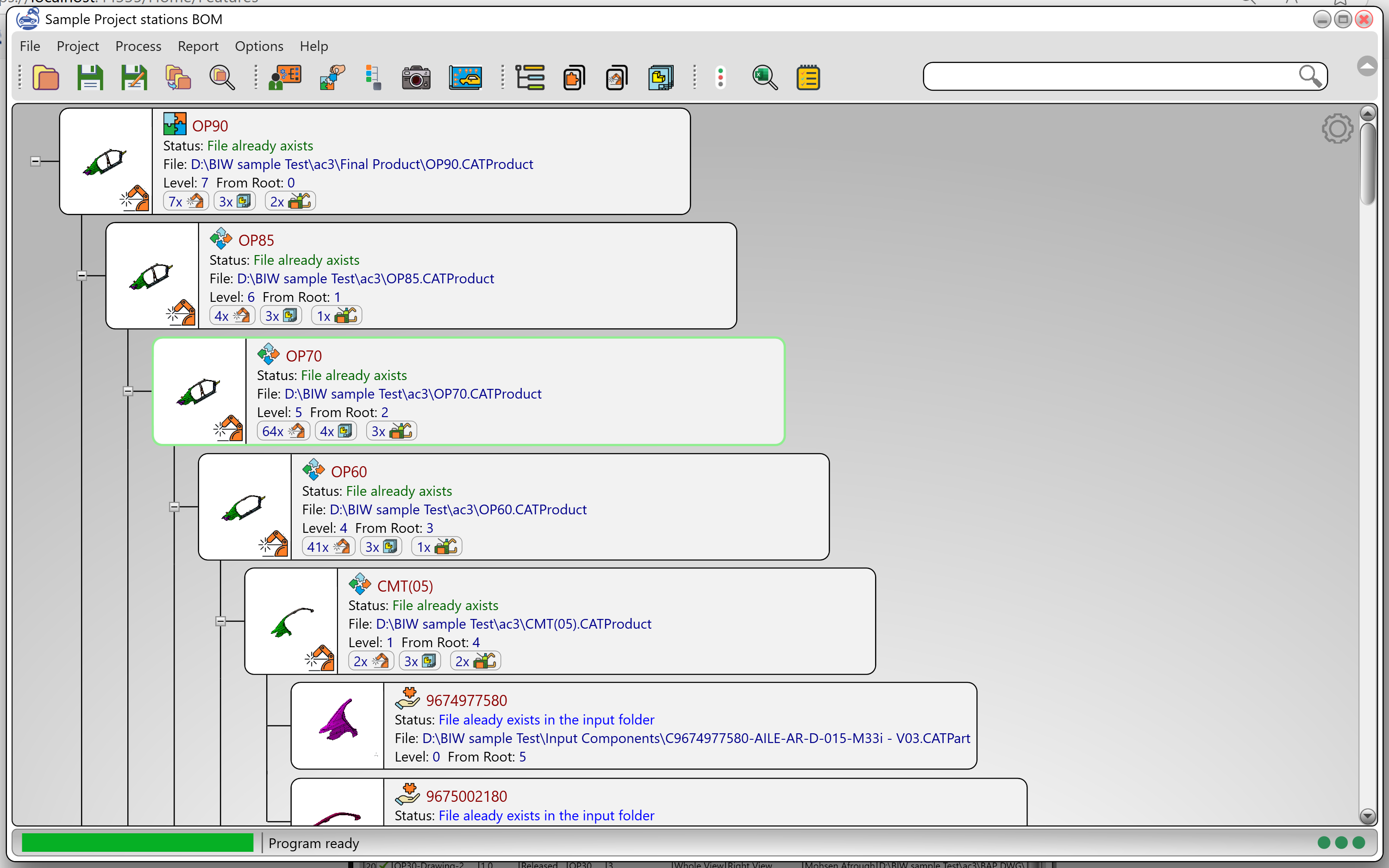

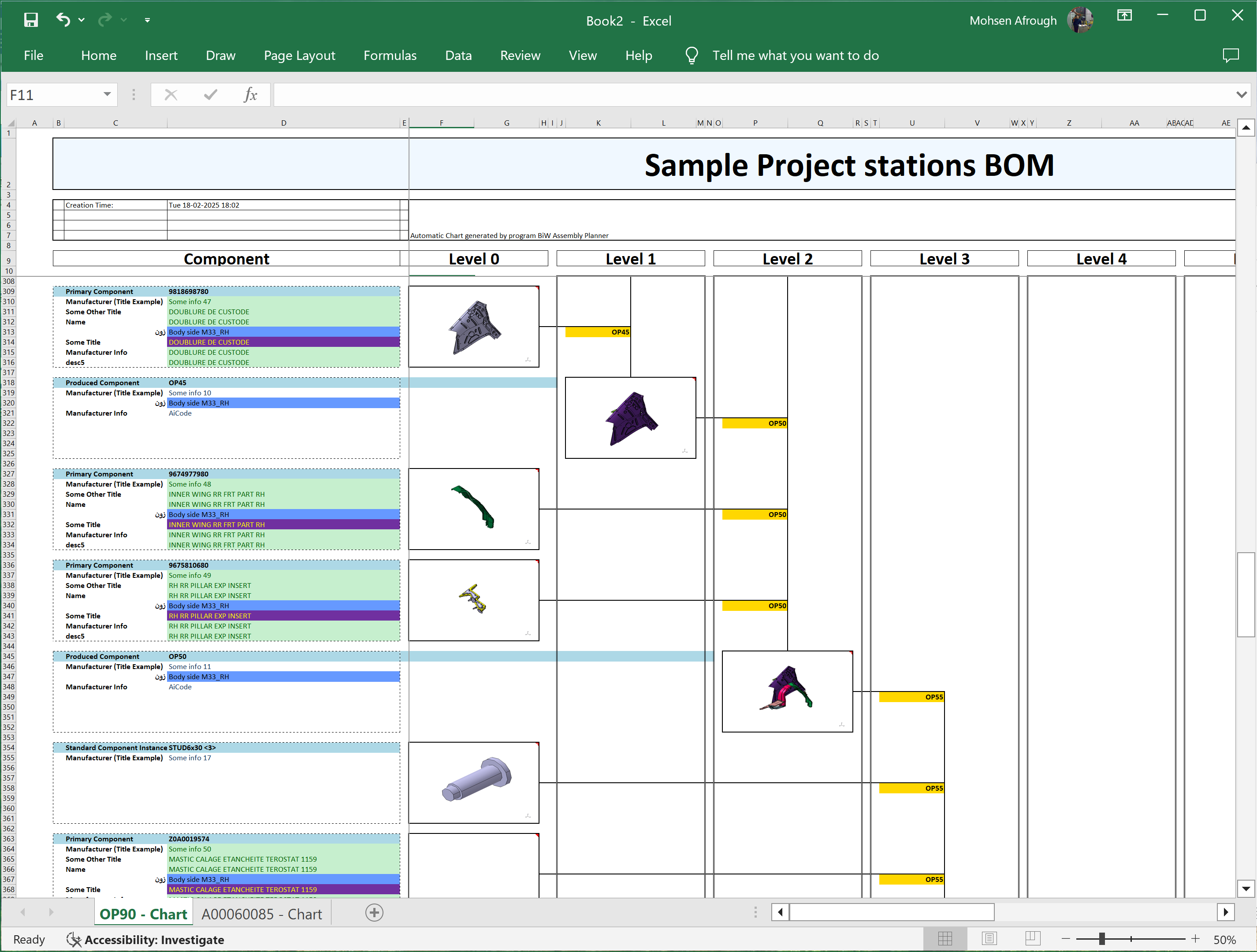

- Creates plant BOM family tree charts in MS-Excel®,

- Generates CAD files for each assembly station,

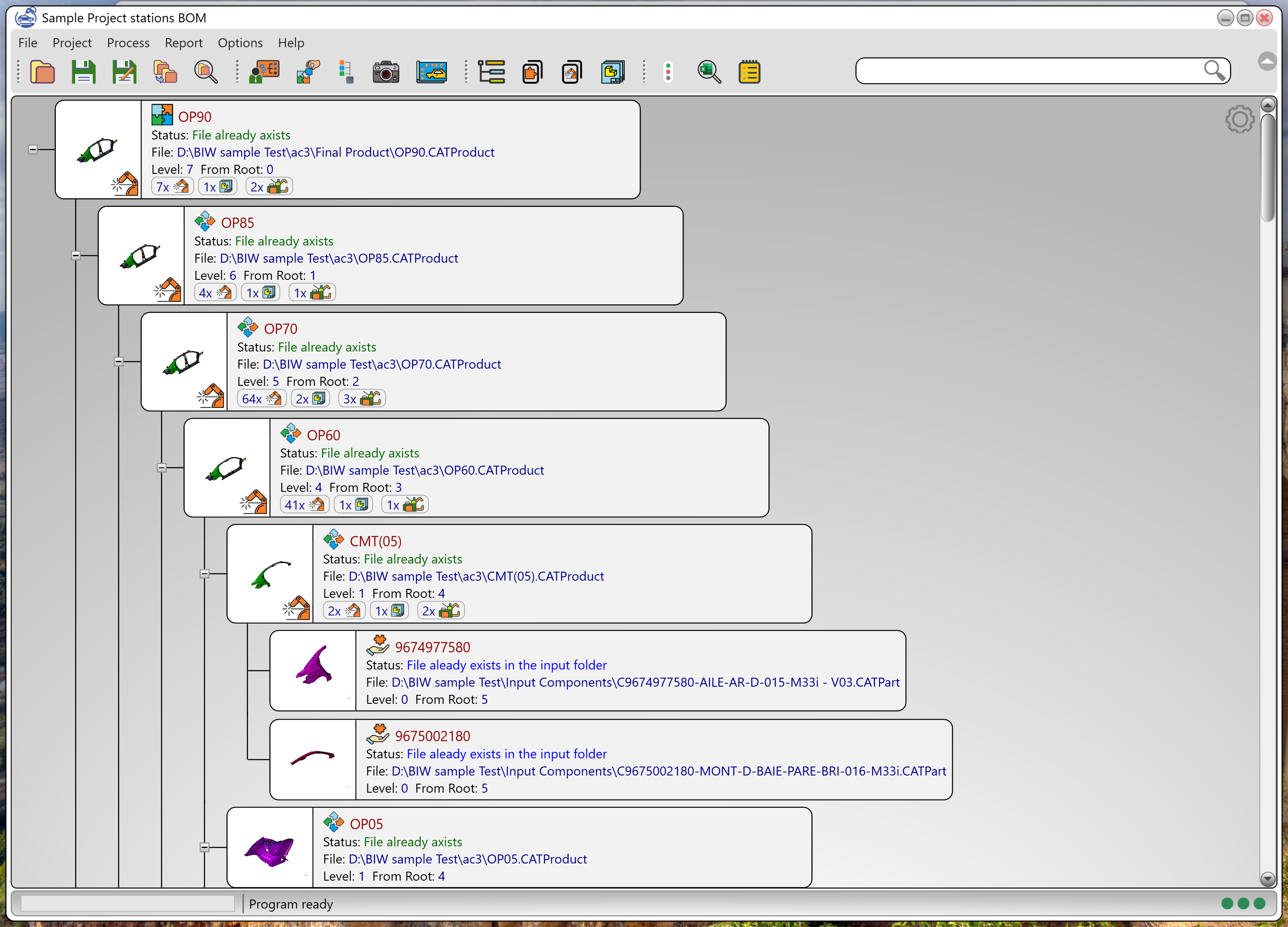

- Visualizes the family tree and data of production stations,

- Stores and manages process definitions of BiW Lines

- Imports and exports process definitions to and from CAD files or MS-Excel® sheets,

- Adds process definitions to CAD files,

- And much more to explore!

Why Choose BiW-AP?

BIW-AP provides an automated solution to streamline your assembly plans into essential documents needed to launch the construction of your production line. It provides benefits like:

- Cut the labor costs: Eliminate hundreds of man-hour labor cost of your project by automatic creation of the drawings, and reports.

- Reduce the project time: Do hours of a human work by a click in BiW-AP, so your documents are ready for starting execution of the project sooner by months.

- Eliminate human errors: Drawings are exact and free of human errors by BiW-AP. BiW Process sheets are one of most human error prone parts of the project, but no more with BiW AP.

- Ensure validity of drawings: It's now automatic! Ensuring validity of drawings by manually tracking of changes through thousands of process definitions for a typical BiW line is cumbersome and error prone.

- Flexibility for changes in the project: By BiW-AP the drawings and documents are easily updated so that makes you more flexible for applying improvements or changes during designing the BiW line.

Key Features of BiW-AP Software

-

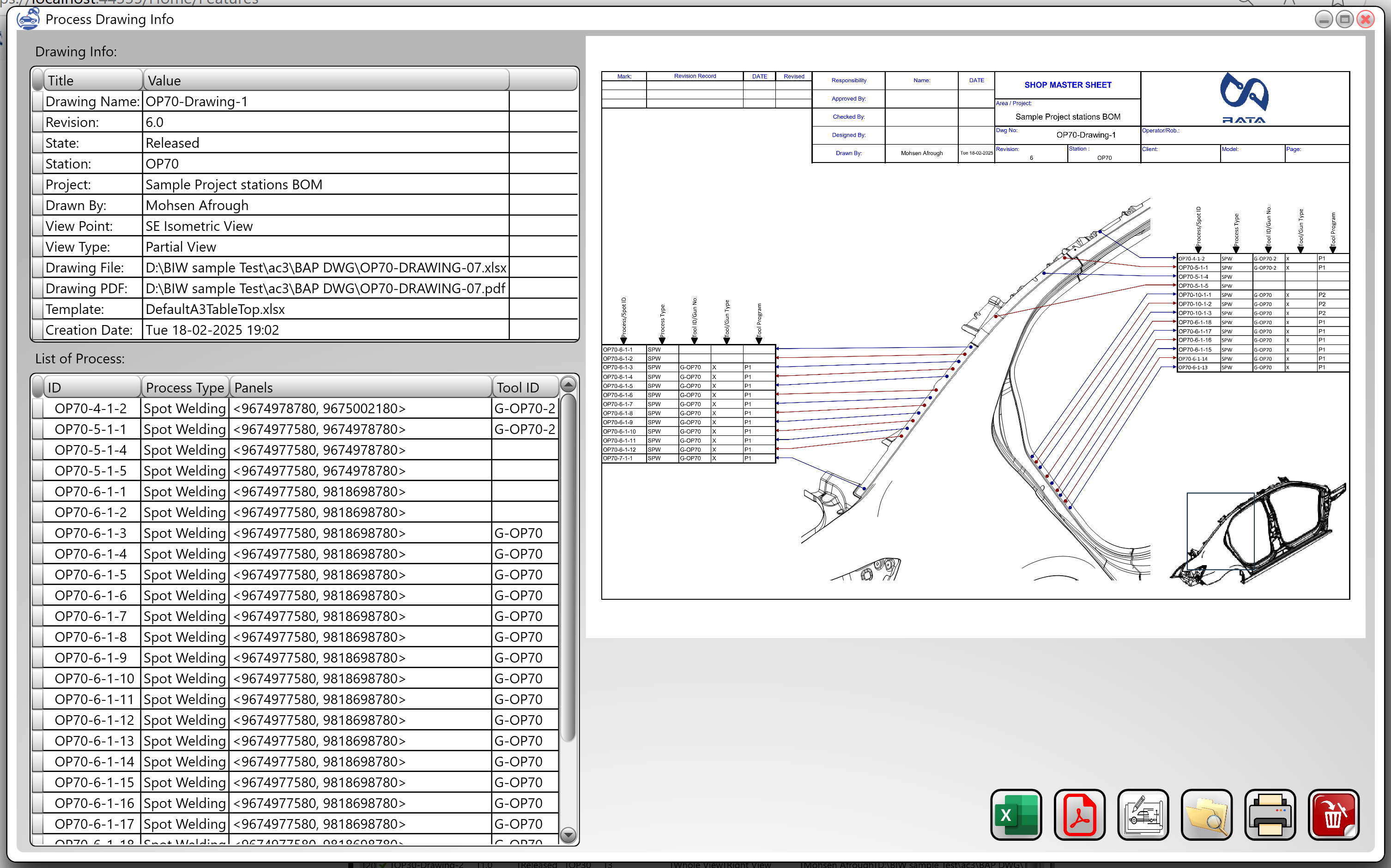

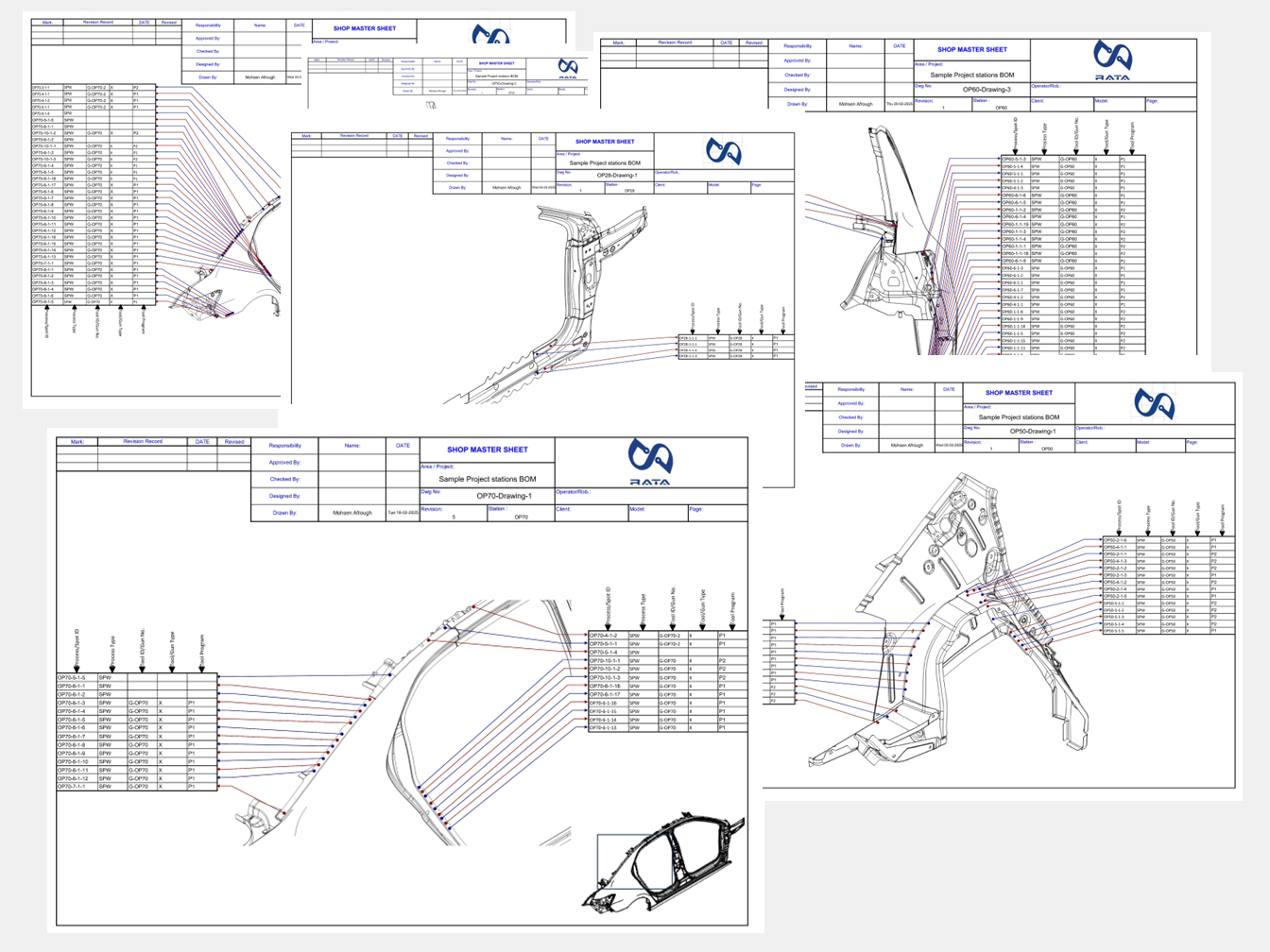

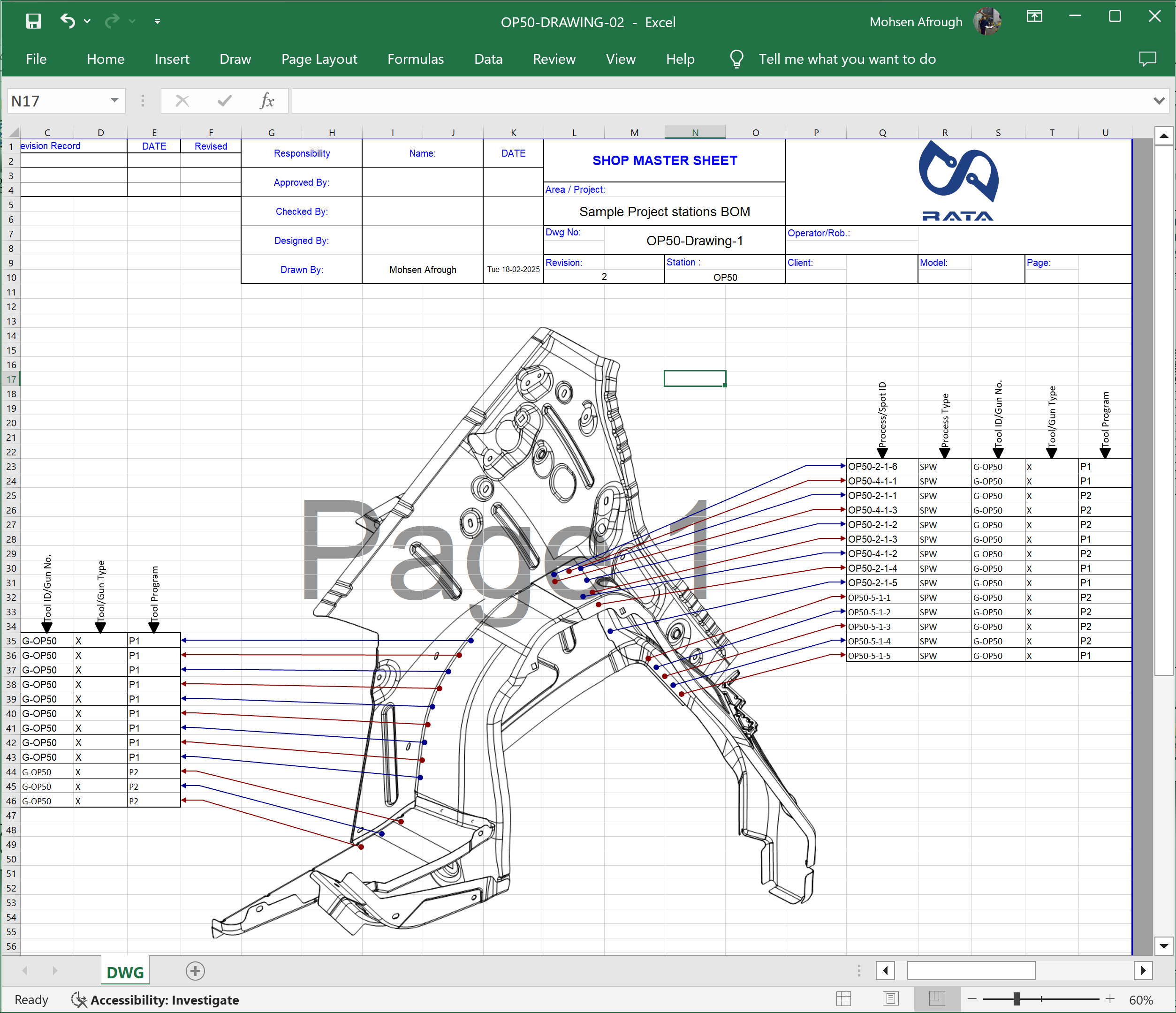

Automatic Creation of Process Sheet Drawings: Generate process sheet drawings in MS-Excel® sheets and PDF. The process sheets are used for tool programming, robot teaching, and personnel training and will be kept as documents needed for maintenance of the production line.

-

Creation of Process Sheet Drawings in MS-Excel®: Process sheet drawings are created in MS-Excel®. So the project enjoys the advantages of publishing drawings in MS-Excel format.

Why Drawings in Excel? Learn about it

-

Aesthetic Placement of Tables and Pointing Arrows: Tables and arrows are elegantly arranged for visual harmony.

-

Ensure Validation of Drawings: Keep your drawings updated and validated continuously throughout your assembly planning phase. Any changes in the assembly process plan, such as displacing process coordinates or moving a process to a different station are immediately reflected in the reports of the project and mark the affected drawings as invalidated.

-

Create Family Tree Chart in MS-Excel®: Save significant time with automated creation of family tree charts in MS-Excel®.

-

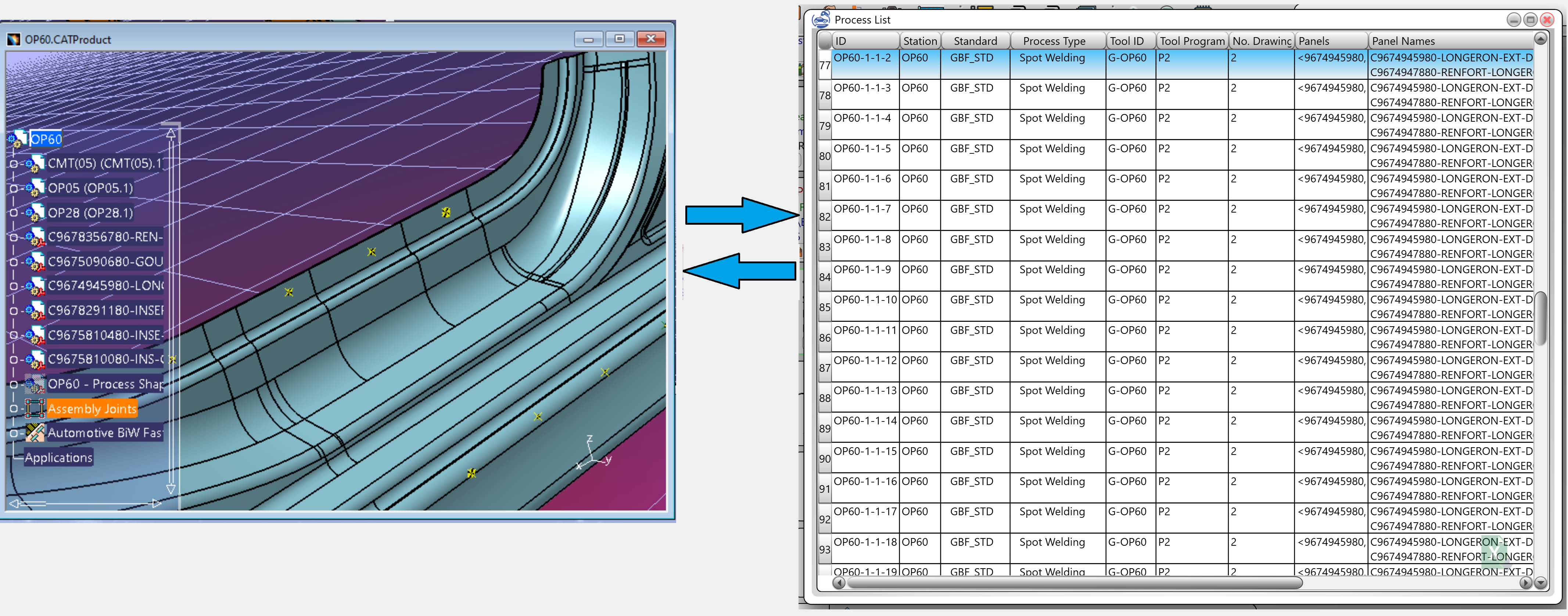

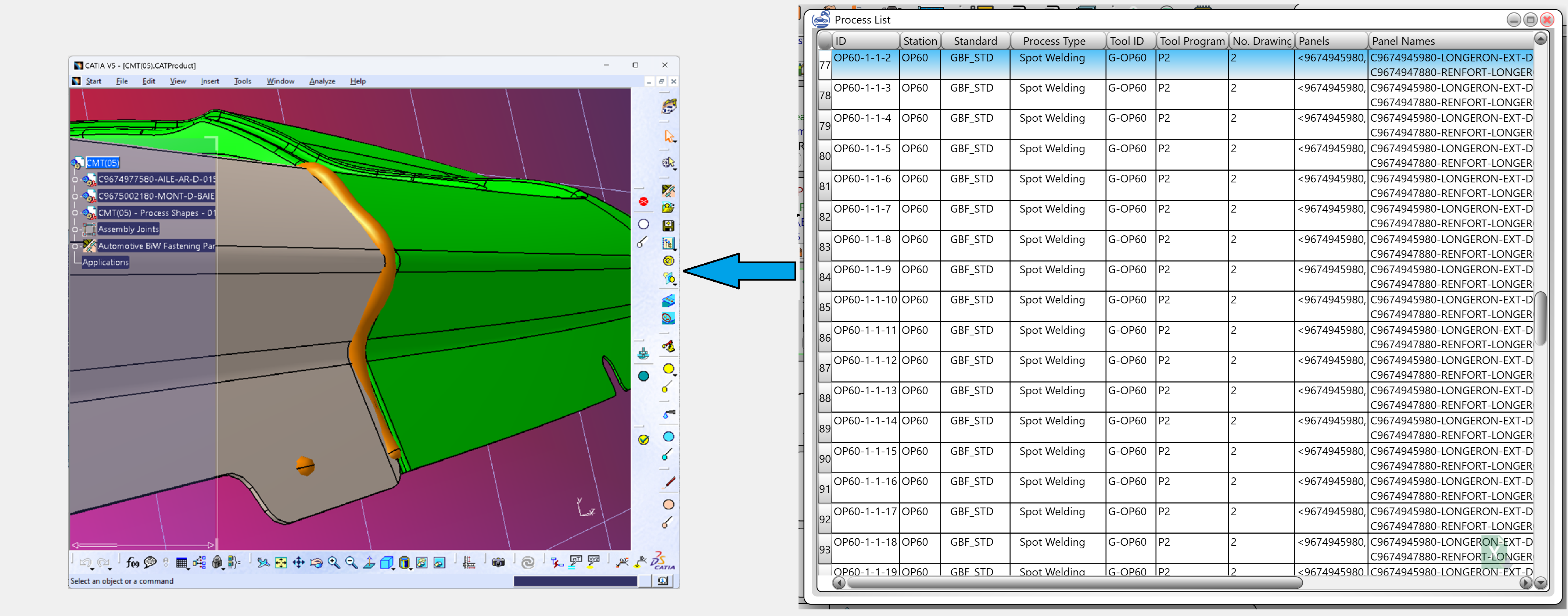

Read or Create CAD Files According to the Plant BOM: MBOM or Plant BOM can be read from existing CATIA® CAD files or MS-Excel® tables whichever available and Create CAD files accordingly if required.

-

Visualize the Family Tree: Visual representation of the product family tree helps to comprehend and improve the Plant BOM.

-

Import Process Definitions from CAD files or MS-Excel® Sheets: Import process definitions from CAD files or MS-Excel® sheets whichever available.

-

Add Process Definitions to CAD Files: Add process definitions to cad files using either BiW fastening module in Catia® or Catia® body shapes.

-

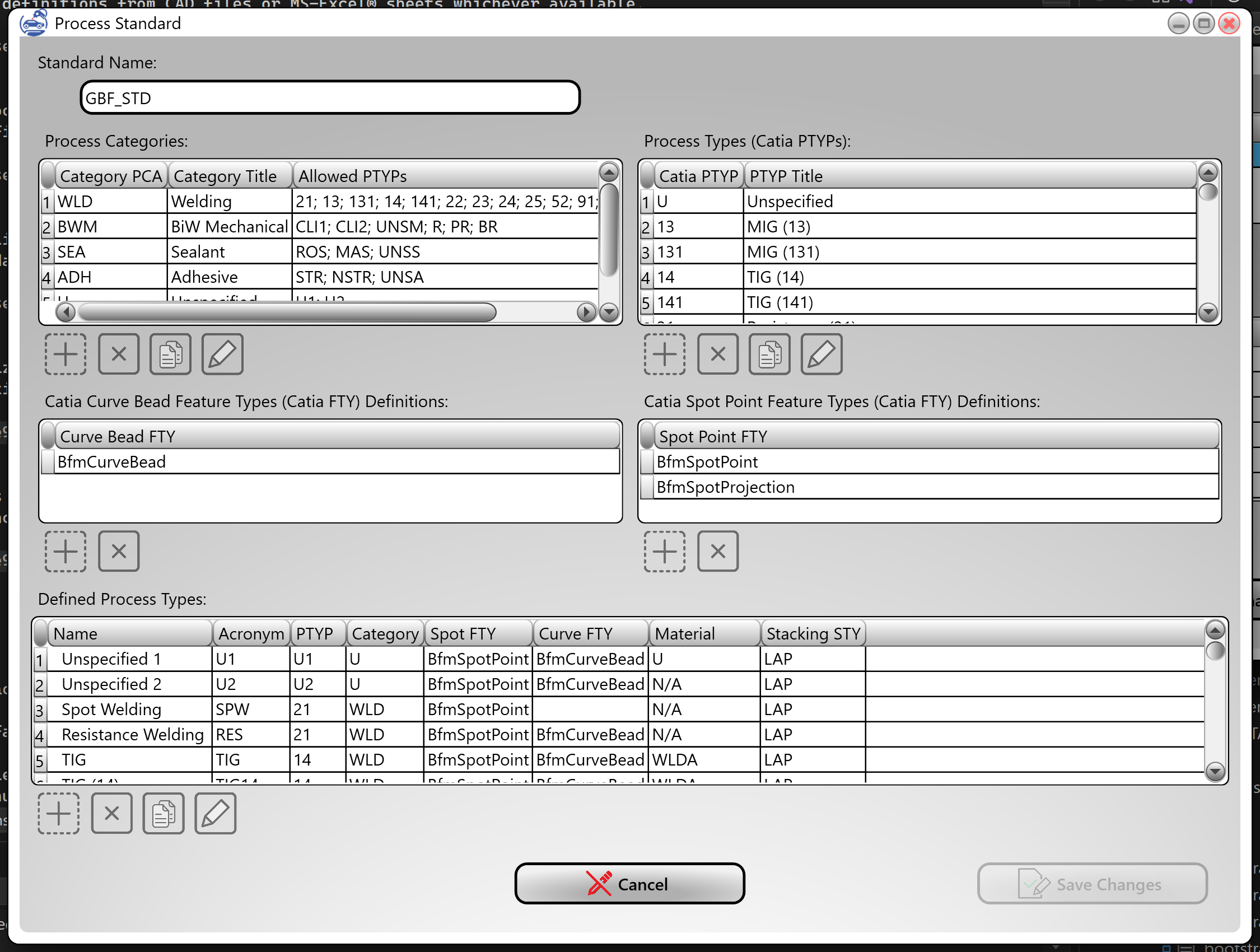

Covers Various Process Types: Various process types like Spot Welding, MIG / TIG or Laser Welding, Sealing and Glueing etc. are handled.

-

Customizable Process Definition Standards: Process definitions are customizable to suit your company specific standards.

-

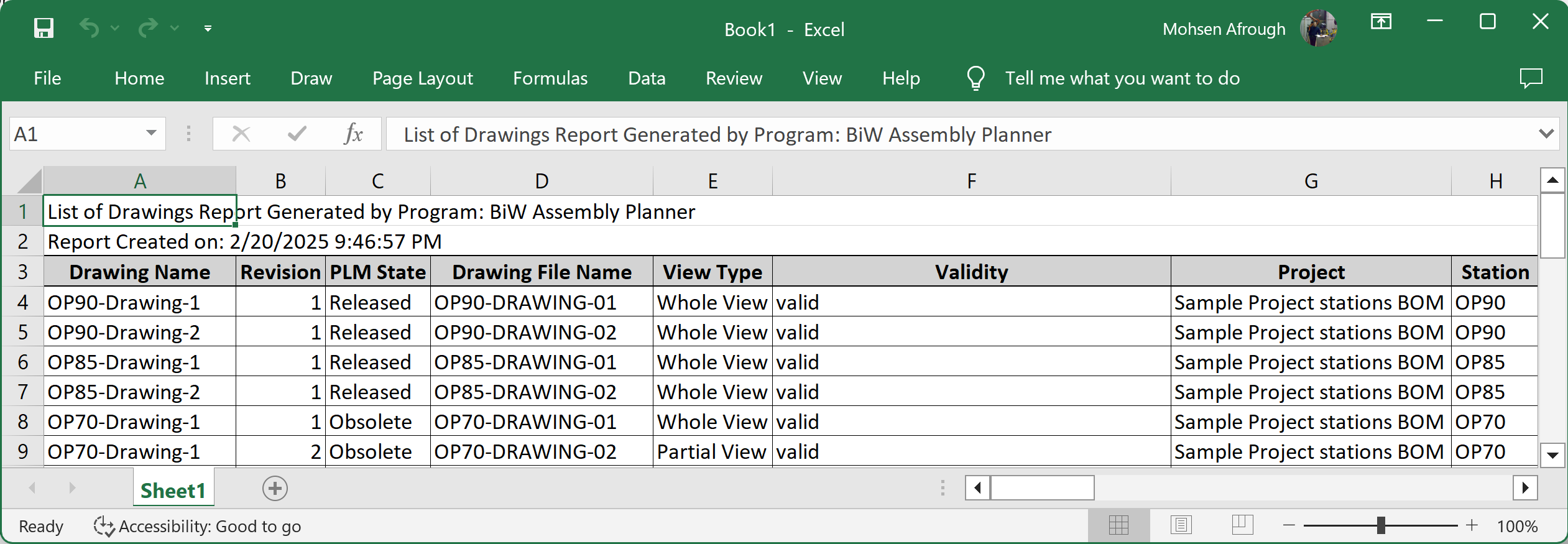

Reports in MS-Excel® Sheets: Project data such as process BOM, components of plant BOM, assembly stations, tools etc. can be reported from the project into MS-Excel® Sheets.

-

Movability: Plan the same project with different process plans. Easily update data and ensure consistency across different project data.

-

Friendly and Productive User Interface: User friendly visualized data and functions of program lets you find your desired command or data without waste of time.